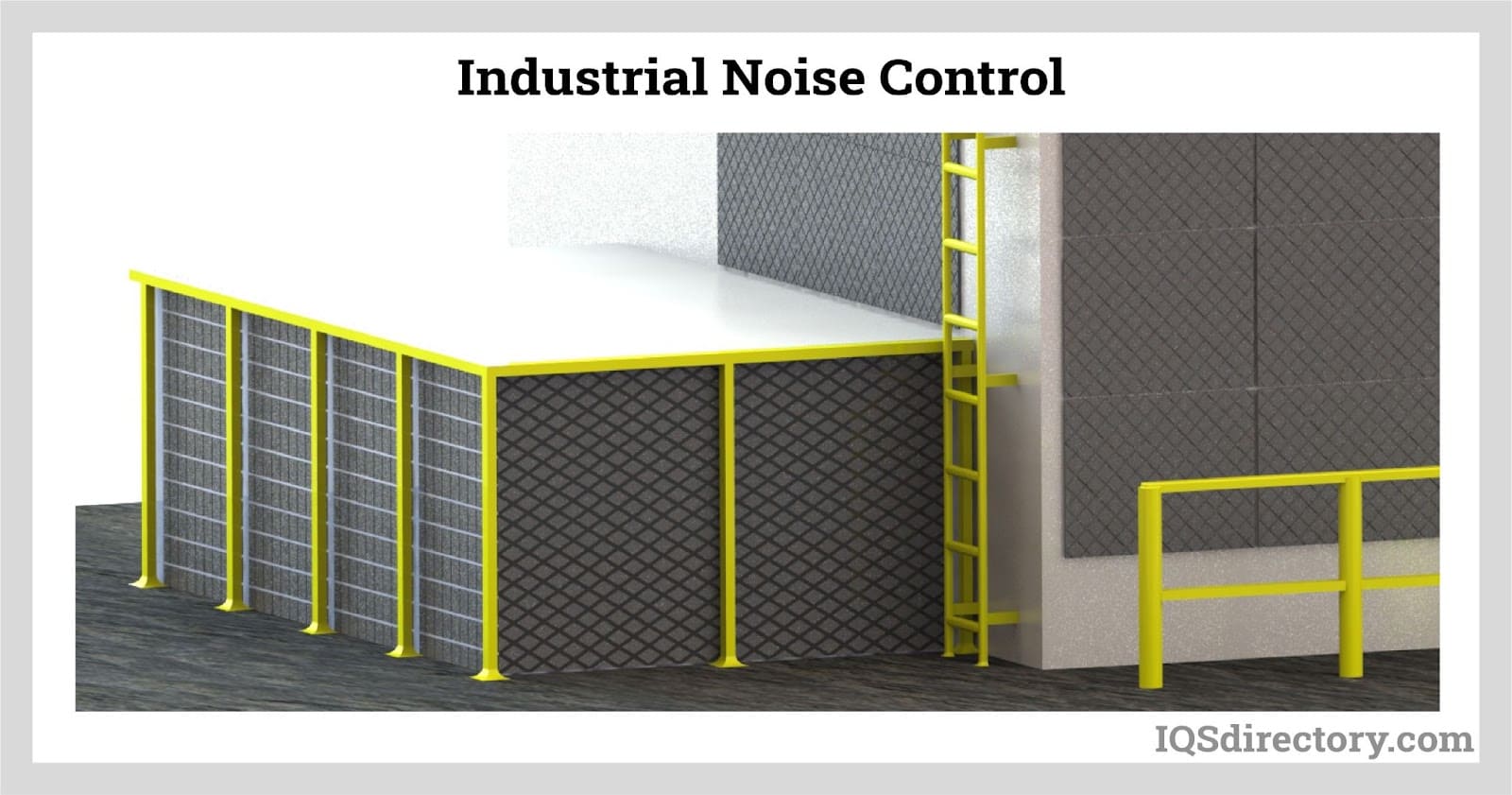

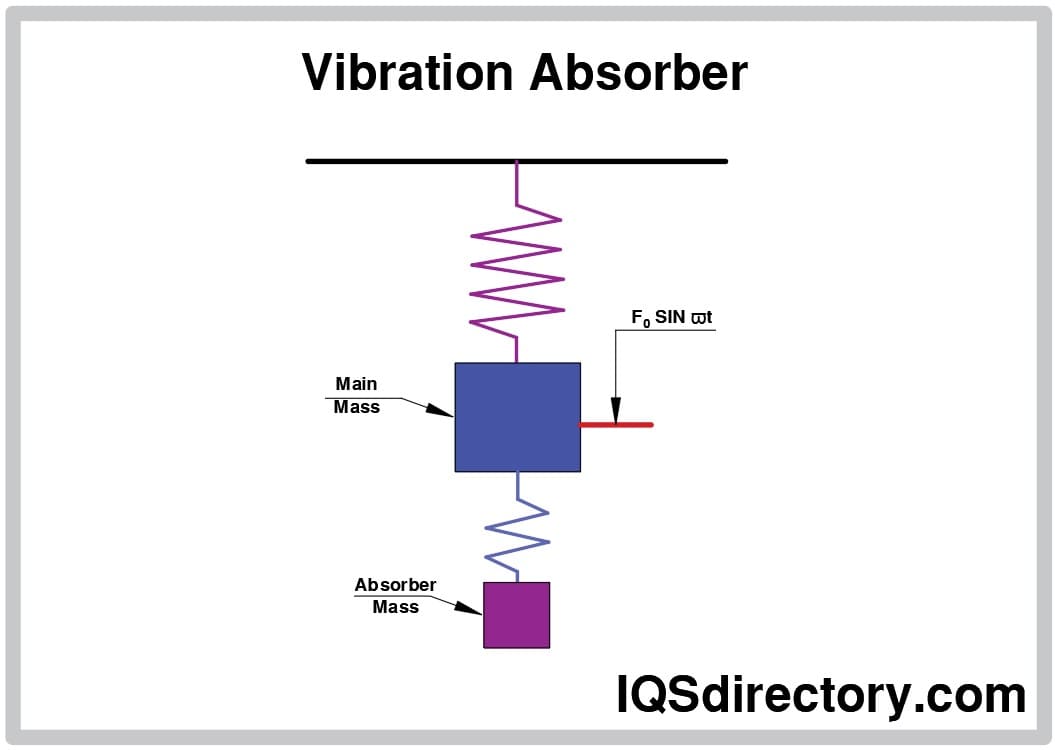

Soundproofing is often used to control the amount of noise in an environment. In order to do this, multiple methods can be used such as absorbing sound, dampening vibrations, or sounds barriers. Read More…

Founded in 2019, DDS Acoustical Specialties stands at the forefront of the acoustic solutions industry, boasting a cumulative experience of more than 45 years. With a commitment to excellence, we specialize in the design, management, and installation of cutting-edge noise control and soundproofing products that cater to the unique needs of businesses across the nation. As we continue to evolve...

Netwell specializes in soundproofing solutions by means of sound barriers and sound absorbers. We have an extensive product line of acoustic panels and over 60 other soundproofing materials in a variety of colors, shapes and sizes tailored to address your specific soundproofing needs. Check us out.

McGill AirPressure Corp. provides noise control solutions for a broad range of industrial and HVAC applications. Our engineered acoustical systems and products include wall panels, sound barriers, acoustical curtain enclosures, barriers and sound absorbers.

Metal Form Mfg. has over 40 years experience in designing and manufacturing soundproofing, air control and evaporative cooling products. Our Commercial Acoustics group provides noise control solutions with our acoustical panels and louvers, equipment sound enclosures, silencers and more.

Isotech, Inc. offers a wide range of Noise Barrier products to contain/reduce/block the noise path. These include flexible portable or permanent enclosures or sheets and rolls of mass loaded vinyls, quilted barrier composites and absorber barrier composites. A noise barrier treatment is extremely effective in reducing overall noise levels depending on the extent that the noise barrier blocks the...

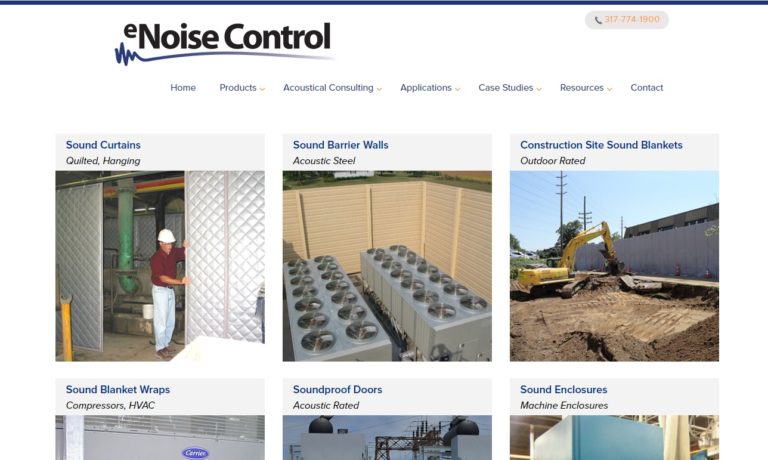

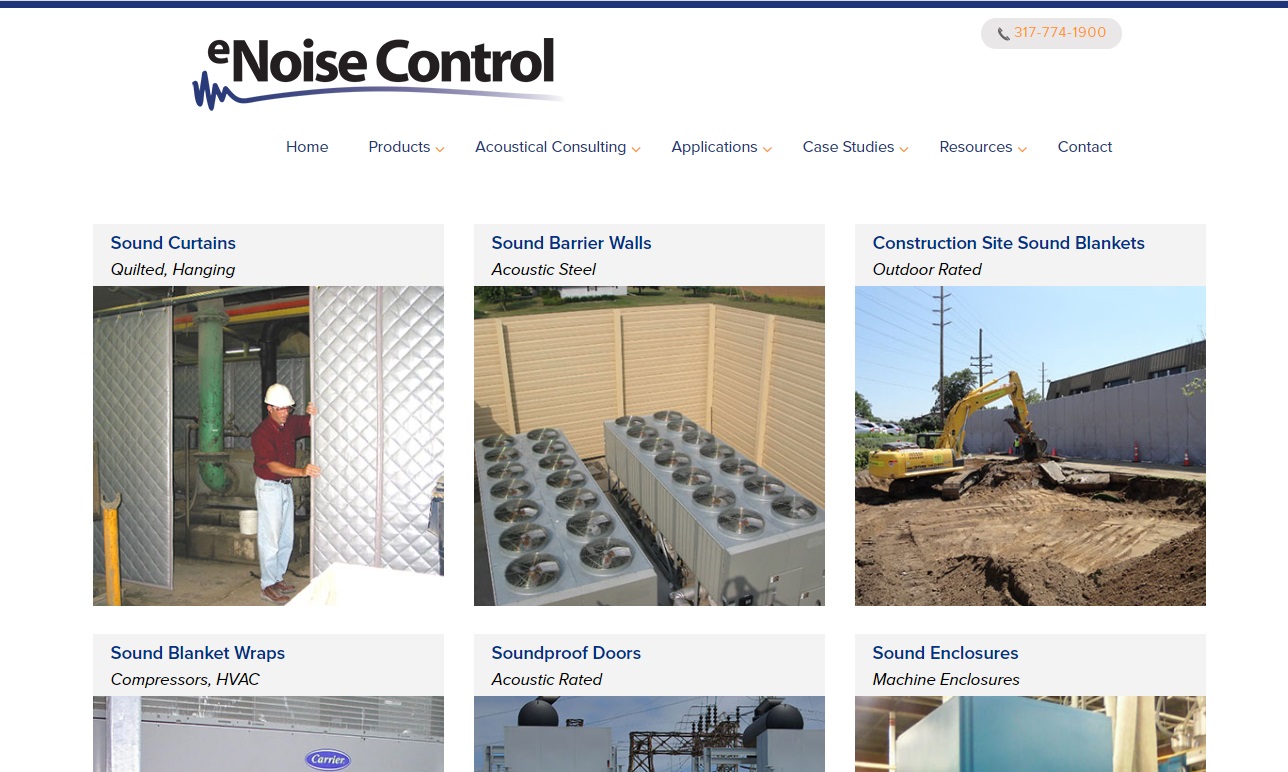

eNoise Control is your source for industrial noise control products such as enclosures, anechoic chambers, acoustical material, sound curtains, sound proofing, vibration isolation, duct lagging, barriers, floating floors, and more. Our sound control experts can answer any question you may have.

Fabricating Services provides insulation products and services for thermal, acoustical and noise control needs. We offer insulation lamination, die cutting and fabrication of sound control and thermal barrier products for many companies in the appliance, automotive and aerospace industries.

ATS acoustical and thermal insulation treatment systems are the solution to your acoustical, thermal, lighting and design problems. Our unique soundproofing materials offer noise reduction and aesthetics with availability in a variety of colors and textures to suit your soundproofing and design needs. These environmentally friendly products are cost-effective in renovations and new construction.

More Soundproofing Material Companies

Noise absorption materials suppress echoes, reflections, resonance, and reverberations whereas noise reducing materials lessen the energy of the sound waves. Before implementing soundproofing materials, it is important to research the best solution for each application. Some components are used in conjunction with each other and others may be used if the space allows. A variety of industries utilize soundproofing materials such as industrial, commercial, and even residential to make places acoustically pleasant. Common places include recording studios, edit rooms, research facilities, function halls, gyms, and even upgraded laundry rooms. To block noise for industrial workers, acoustic curtains are often used when need be.

Soundproofing involves using materials that are able to trap noise and prevent reverberations that would send noise pollution back into the space. Materials that are corrugated, uneven, or jagged in appearance are the most effective because they increase the ratio of the sound barrier and opening space. They allow the sound waves to dissipate more fully and absorb noise. Examples of this can be foam, wedges, rock wool, sheetrock, high mass vinyl, fiberglass, rubber, aluminum, composite, glass, polyethylene, mineral wool, and soundboard. Mineral wool fibers are good example of soundproofing options that are non-combustible and have high melting points allowing them to be used around heat generating industrial machines without serious risks. These materials can be applied during or after construction of a space, however post-construction soundproofing is often far less effective than installing a sound-proofing material from the beginning.

Machine Guards

Machine Guards Noise Control

Noise Control Safety Cables

Safety Cables Sewing Contractors

Sewing Contractors Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services